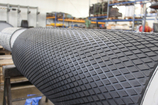

Rubber pulley laggings and ceramic pulley laggings for conveyor belt pulleys

Grip Guaranteed for Conveyor Belt Pulleys

Our germanGrip® pulley laggings minimize wear on conveyor belt pulleys and help to meet our clients’ ever increasing requirements. Optimized frictional coefficients reduced belt tension and eliminate undesired pulley bearing failure. The laggings and the minimized belt slip they achieve leads to a reduction in wear and tear on the contact surface, and to improved force transmission.

The conveyor belt system’s lifespan is likewise increased, making the plant more profitable. The combination of our pulley laggings with our germanBond® high performance adhesives makes sure that the forces required are applied to the places where their effect is the most efficient.

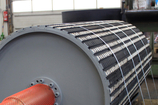

Ceramic Pulley Laggings

germanGrip® pulley laggings with ceramic modules display, compared to viscoelastic materials (elastomers), outstanding and proven wear behaviour. They are marked by significantly increased abrasion resistance while providing the highest friction forces to the friction partner. The design as ceramic friction module with a flexible elastomeric substructure is, in terms of pulley laggings, an ideal combination of materials that synergistically combines the benefits of its individual components.

germanGrip® Cera with CN Layer

Specifications:

Detailed profile: 20 x 20 x 4 mm

Base-Rubber Characteristics:

Density: 1.13 ±0.03 g/cm³

Hardness: 60 ±5 ° Shore A

Tensile strength: ≥ 400 %

Abrasion: ≤ 130 mm³

Available dimensions:

Thickness: 12 mm

Width: 385 mm

Available length: 10 m

Downloads:

germanGrip® Cera basic with CN Layer

Specifications:

Detailed profile: 20 x 20 x 4 mm

Base-Rubber Characteristics:

Density: 1.13 ±0.03 g/cm³

Hardness: 60 ±5 ° Shore A

Tensile strength: ≥ 400 %

Abrasion: ≤ 130 mm³

Available dimensions:

Thickness: 12 mm

Width: 385 mm

Available length: 10 m

Downloads:

Rubber Pulley Laggings

Our rubber laggings for conveyor belt pulleys provide optimal force transmission at a high lifespan. Even in wet and muddy conditions the friction material for pulley laggings ensures optimal grip. Rely on germanGrip® rubber lagging materials and reduce slip and wear on belt and pulleys. Protect the components of your conveyor belt system with our pulley laggings.

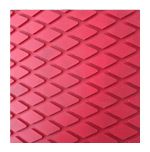

germanGrip® MR 45 Red with CN Layer

Specifications:

Colour: red

Detailed profile: 34 x 17 x 3 mm [small diamond groove]

Density: 1.08 ±0.03 g/cm³

Hardness: 40 ±5 ° Shore A

Tensile strength: ≥650 %

Abrasion: ≤ 85 mm³ at 5 N

Available dimensions:

Thickness: 8 / 10 mm

Width: 1.500 / 2.000 mm

Available length: 10 / 20 / 30 / 40 / 50 m

Downloads:

germanGrip® MR 60 Black with CN Layer

Specifications:

Colour: black

Detailed profile: 34 x 17 x 3 mm [small diamond groove]

Density: 1.13 ±0.03 g/cm³

Hardness: 60 ±5 ° Shore A

Tensile strength: ≥ 400 %

Abrasion: ≤ 130 mm³

Available dimensions:

Thickness: 8 / 10 mm

Width: 1.500 / 2.000 mm

Available length: 10 / 20 / 30 / 40 / 50 m

Downloads: